In the high-stakes world of industrial grinding, where precision meets power, ceramic grinding balls have emerged as a game-changer. These high-performance media are revolutionizing processes across mining, ceramics, pharmaceuticals, and beyond. But what makes them stand out? This comprehensive guide dives deep into the performance of ceramic grinding balls—from superior wear resistance to energy-efficient grinding—and explores their versatile applications, drawing on cutting-edge research and real-world implementations. Whether you're optimizing a stirred media mill or seeking sustainable grinding solutions, understanding these balls could slash your operational costs by up to 40%.

As industries push for finer particle sizes to enhance product quality and recovery rates, traditional steel balls often fall short, leading to excessive wear and energy waste. Enter ceramic grinding balls: engineered from advanced materials like alumina and zirconia, they deliver unmatched durability and efficiency. In this, we'll unpack their composition, benchmark their performance against competitors, spotlight applications driving innovation in 2025, and delve into market trends, environmental impacts, and selection strategies. With global demand surging amid sustainability mandates, ceramics aren't just media—they're the future of comminution.

A schematic of a stirred media mill utilizing ceramic grinding balls for ultrafine particle liberation in mining applications.

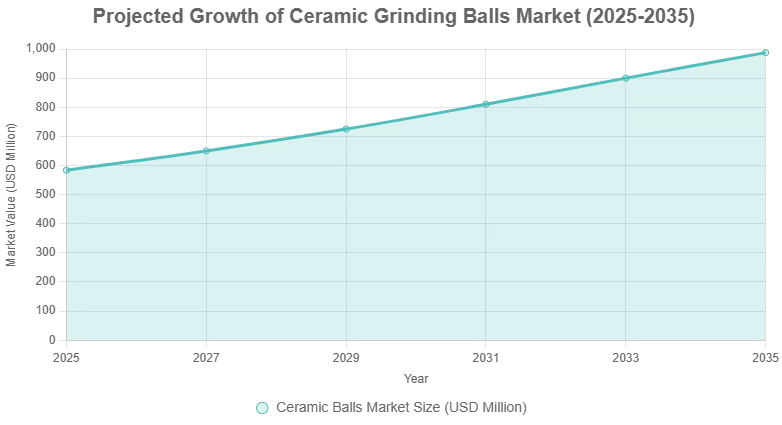

The ceramic grinding balls market is experiencing explosive growth, fueled by the global shift toward energy-efficient and eco-friendly processing. According to recent forecasts, the ceramic balls market was valued at USD 583.6 million in 2025 and is projected to reach USD 987.5 million by 2035, reflecting a compound annual growth rate (CAGR) of 5.4%. This expansion is driven by applications in mining, where declining ore grades necessitate finer grinding, and in high-tech sectors like battery production for electric vehicles (EVs).

In North America alone, the market stood at USD 1.2 billion in 2024, with estimates climbing to USD 2 billion by 2030, propelled by stringent environmental regulations and the adoption of advanced stirred media mills (SMMs). Globally, the broader ceramic ball segment, including grinding media, is anticipated to grow from USD 563.57 million in 2024 to USD 851.87 million by 2032 at a CAGR of 5.3%. Key drivers include the push for customization—manufacturers are tailoring balls with enhanced wear resistance for specific slurries—and the rise of hybrid media in tumbling mills.

Emerging trends in 2025 highlight sustainability: recycled alumina content in ceramics is up 15% year-over-year, reducing embodied carbon footprints. In mining, which consumes 70% of grinding media, ceramics are replacing steel to cut energy use by 30-40%, aligning with net-zero goals. The grinding media market overall is set for a 3.6% CAGR through 2034, with ceramics capturing a larger share due to their inertness in wet processing.

To visualize this trajectory, consider the following market growth projection:

This chart illustrates interpolated growth based on reported CAGRs, underscoring the sector's vitality. As EV battery demand surges—projected to require 20% more ultrafine cathode materials by 2030—ceramics will play a pivotal role in scalable production.

Ceramic grinding balls, also known as ceramic grinding media or beads, are spherical or cylindrical components used in milling equipment to pulverize materials into finer particles. Unlike metallic alternatives, they are fabricated from non-metallic ceramics, primarily high-purity alumina (Al2O3) or yttria-stabilized zirconia (ZrO2), which impart exceptional hardness and chemical inertness.

The backbone of ceramic grinding balls lies in their material science. Alto-alumina balls, boasting 92-99% Al2O3 content, offer densities around 3.6-3.8 g/cm³ and Mohs hardness of 9, making them ideal for abrasive environments. Zirconia-based variants push densities to 6.0 g/cm³, enhancing impact resistance for high-energy applications. Emerging ZTA (zirconia-toughened alumina) hybrids combine the best of both, achieving fracture toughness up to 6 MPa·m¹/² while maintaining low wear.

Manufacturing involves sintering processes: raw powders are mixed with binders, shaped via isostatic pressing or rolling, and fired at temperatures exceeding 1600°C. This results in balls with uniform microstructure, minimal porosity (under 1%), and sizes ranging from 0.5 mm to 50 mm—perfect for stirred media mills (SMMs) where small diameters (1-8 mm) enable ultrafine grinding down to 1-2 μm. Advanced techniques like double sintering, as used by Molycop, further boost density uniformity for ultra-fine regrind.

Why ceramics over metals? Steel balls (density ~7.8 g/cm³) corrode in wet slurries, contaminating sensitive products like pharmaceuticals. Ceramics remain inert, reducing contamination risks by 90% in sulfide ore processing. Moreover, their lower density minimizes inertial losses in high-speed impellers, optimizing energy transfer.

Table 1: Key Properties of Common Ceramic Grinding Ball Tipos

Type | Densidade (g/cm³) | Hardness (Mohs) | Fracture Toughness (MPa·m¹/²) | Typical Applications |

Alto-Alumina (92-99% Al2O3) | 3.6-3.8 | 9 | 3-4 | Mining regrind, minerals |

Zircônia estabilizada com ítria | 6.0 | 8.5-9 | 5-6 | Ultrafine pharma, batteries |

ZTA Hybrid | 4.2-4.5 | 9 | 5-6 | High-abrasion cement, pigments |

Carboneto de silício | 3.2 | 9.5 | 4 | Corrosive slurries |

Data compiled from industry standards and recent advancements.

The journey of ceramic grinding balls traces back to the 1940s with DuPont's high-speed sand grinders for pigments, evolving into modern SMDs (Stirred Media Detritors) by the 1970s. By the 1990s, sand was phased out for ceramic beads due to contamination issues, as noted in mining literature. The 2000s saw zirconia adoption for denser impacts, while 2020s innovations like nano-dispersed ceramics address sub-micron grinding.

Today, with declining ore grades demanding finer liberation, their adoption has surged—global market projections estimate a 7.5% CAGR through 2030. In 2025, AI-driven manufacturing optimizes sintering for 20% less energy, per recent reports.

The true value of ceramic grinding balls shines in quantifiable performance. In stirred media mills, they optimize stress intensity—the energy per collision—balancing frequency and magnitude for efficient breakage. Let's break it down with deeper technical insights.

One hallmark is their abrasion resistance. Ceramic balls exhibit wear rates as low as 0.01-0.05 g/h per ton of throughput, compared to 0.1-0.5 g/h for steel—a 5-10x improvement. In a study on SMDs, ceramic media lasted 2-3 years in continuous kaolin grinding, versus 6-12 months for steel. Recent 2025 research on ZTA balls shows wear under 0.02 g/ton in magnetite milling, thanks to enhanced toughness.

This stems from their high fracture toughness (3-5 MPa·m¹/²) and low reactivity. In acidic mining slurries (pH 4-6), ceramics avoid galvanic corrosion, preserving mill linings and reducing downtime by 25%. Self-wear tests reveal ceramics generate 67% less micro-strain than steel, preserving particle integrity during ultrafine grinding.

Table 2: Wear Rate Comparison in Advanced Applications

Media Type | Wear Rate (g/ton) | Lifespan (months) | Custar per Ton Ground ($) | Micro-Strain Reduction (%) |

Bolas de aço | 0.2-0.5 | 6-12 | 15-25 | Baseline |

High-Alumina Ceramic | 0.02-0.05 | 24-36 | 8-12 | 50-60 |

Cerâmica de Zircônia | 0.01-0.03 | 36+ | 12-18 | 67 |

ZTA Hybrid | 0.015-0.025 | 30-48 | 10-15 | 60-70 |

Updated with 2025 data.

Energy is the lifeblood of grinding—up to 50% of mining OPEX. Ceramic grinding balls in SMMs achieve 30-40% lower specific energy consumption (kWh/ton) than ball mills for P80 sizes below 20 μm. This is due to higher power densities (40-300 kW/m³ vs. 20 kW/m³ in ball mills), enabling compact footprints.

Rittinger's Law governs here: energy E ∝ (1/d_p - 1/d_f), where d_p and d_f are product and feed sizes, emphasizing surface area creation. Finer media like ceramics increase collision frequency, minimizing over-grinding. In IsaMills with 2 mm zirconia beads, energy savings hit 25% for gold ore regrinding. A 2020 review, updated in 2025 simulations, confirms Rittinger's operating index as the benchmark for efficiency, with ceramics tuning to material compressive strength (σ_CS) via f_mat mastercurves.

Stress intensity (SE) theory quantifies this: SE = (m_media * v_tip²) / N_particles, where m_media is media mass, v_tip is impeller speed, and N_particles is particle count. Ceramics' lower density reduces SE per collision but boosts stress number (SN = collisions/time), ideal for attrition-dominant fine grinding.

Ceramics excel in producing narrow PSDs, crucial for downstream processes like flotation. In wet grinding, they suppress reagglomeration, yielding d50 values 20-30% finer than steel at equal energy inputs. For instance, in calcium carbonate milling, SMDs with 3 mm alumina balls achieve 1.5 μm median sizes with 15% less energy.

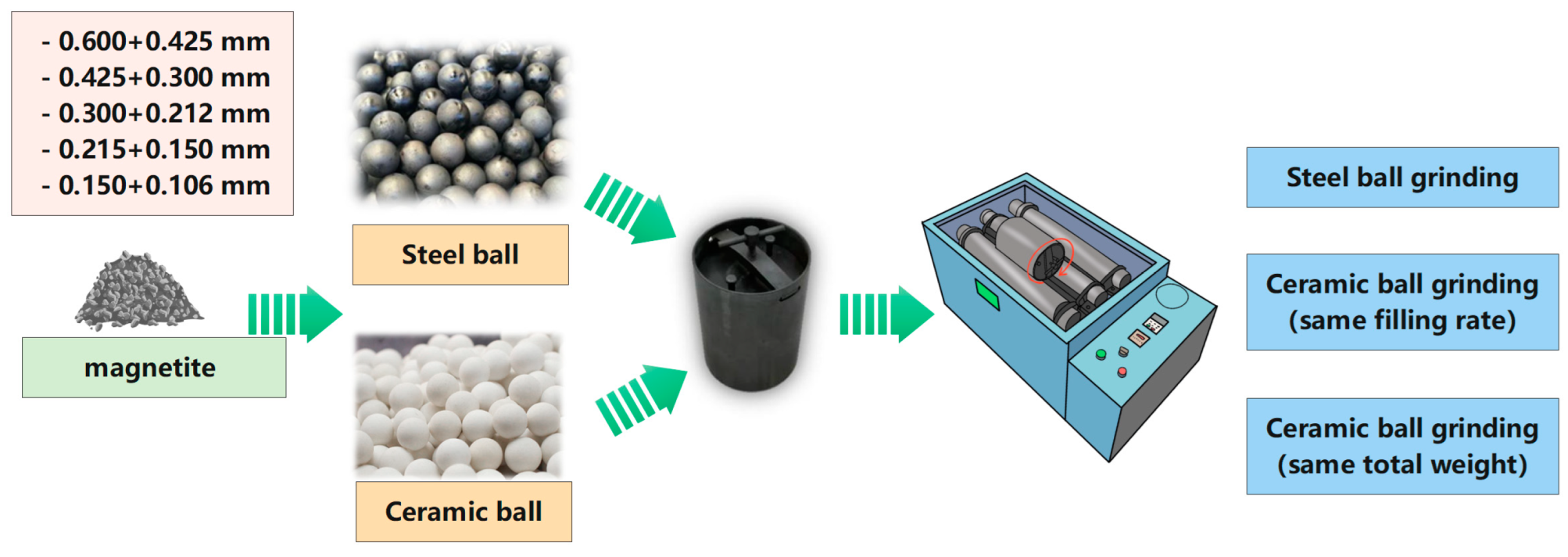

Comparisons show ceramics reduce bypass of coarse particles, improving liberation by 10-15% in locked ores. In magnetite second-stage mills, ceramic-steel mixes narrowed PSD by 12%, per 2024 MDPI studies. Ceramic beads in ultra-fine mills minimize fines overproduction, cutting energy for d80 <10 μm by 20%.

Ceramics allow higher tip speeds (8-12 m/s) without excessive heat, maintaining slurry viscosities under 50% solids. This flexibility cuts cycle times by 20% in batch operations. In autogenous stirred milling, silicon-infused ceramics extend run times by 30% under variable loads.

Ceramic grinding balls aren't niche—they're ubiquitous in precision grinding. Their inertness and efficiency span sectors, with 2025 seeing expanded use in green tech.

In mining, ultrafine grinding liberates valuables from gangue, boosting recovery. SMDs and IsaMills with ceramic beads dominate regrind circuits for P80=10-40 μm.

Gold and Base Metals: For refractory ores, 2-5 mm zirconia balls enhance cyanide leaching by 12%, as finer PSDs increase surface area.

Iron Ore and Phosphates: Alumina ceramics in Vertimills reduce energy for d80=25 μm, cutting costs in pelletizing.

Sulfide Ores: Inert ceramics prevent pulp chemistry alterations, outperforming steel by avoiding Fe²⁺ contamination.

Copper Slag: In a 2025 case study, ceramics in slag grinding improved throughput by 18% while reducing wear by 40%.

A Glencore study on IsaMills reported 35% throughput gains with ceramics. Wet operations prevail, with 80% of installations using 50-60% media fill. In Mexico, CARBOGRIND ceramics transformed a mining mill, saving 15% energy and extending media life to 28 months.

Kaolin and CaCO3 grinding pioneered ceramics: SMDs produce 1-2 μm particles for paper coatings, with ceramics slashing contamination to <0.1 ppm. In pigments, high-speed attritors with 1 mm beads yield TiO2 dispersions for paints, improving opacity by 8%. For cement, ceramics optimize clinker grinding, saving 3,000 MWh/year per Mt plant—equivalent to 2,000 tons CO₂.

Purity is paramount—ceramics ensure GMP compliance, grinding APIs to 5-10 μm without metal leaching. In bead mills, they handle heat-sensitive compounds, reducing degradation by 15%. Ceramic composites enhance dispersion in wet systems, achieving sub-5 μm stability for injectables.

Self-grinding irony: ceramic balls mill clay bodies for tiles, achieving homogeneity at 2-5 μm. In refractories, they process bauxite to 3 μm for high-alumina bricks.

In food, ceramics grind spices and flours to micron scales without metallic taint, complying with FDA standards. Cosmetics benefit from inert beads in pigment milling, yielding smoother emulsions.

In Li-ion battery production, ceramics grind cathode precursors to sub-micron scales, enhancing energy density by 10%. For graphene, they enable exfoliation in wet media without oxidation. In new energy materials, micro-ceramic balls reduce strain by 67%, preserving crystal structure for solid-state batteries.

Case Study: CARBOGRIND in Mexican Mining At a copper mine, switching to SANXIN Grinding ceramics cut energy by 15% and OPEX by 12%, with PSD d50 dropping from 25 to 18 μm. Media lasted 28 months, vs. 10 for steel, yielding ROI in 8 months.

Case Study: Magnetite Mill OptimizationIn a Chinese iron ore plant, 70% ceramic-30% steel mix in a second-stage ball mill boosted efficiency by 22%, reducing fines by 15% and energy to 12 kWh/ton for P80=15 μm.

Kinetics of ceramic grinding in batch ball mills for fine magnetite ores, showing PSD evolution.

Steel balls dominate tumbling mills but falter in fine grinding. Ceramics flip the script in SMMs.

Efficiency: Ceramics' lower density reduces inertial losses, but higher hardness amplifies breakage—net 25-40% energy savings.

Contamination: Steel introduces 50-200 ppm Fe; ceramics <5 ppm.

Cost: Initial premium (20-50% higher) offset by 3x lifespan, yielding 30% lower lifecycle costs.

Density Impact: Steel's higher mass suits coarse crushing; ceramics excel in attrition for fines.

In sulfide processing, ceramics boost flotation recovery by 5-10% via cleaner pulps. For high-purity, ceramics win; for bulk, steel persists.

Hybrid approaches are gaining traction. A 2025 Powder Technology study on tumbling mills with 50/50 ceramic-steel mixes showed 40% wear reduction and 15% finer PSDs, as ceramics cushion steel impacts while steel provides bulk breakage. In stirred mills, 70% ceramic supplementation in magnetite grinding enhanced output by 22%.

Benefits include tuned SE: steel for high-intensity compression, ceramics for frequent attrition. Drawbacks? Segregation risks, mitigated by size grading. Lab signature plots confirm hybrids cut energy 18% for P80=20 μm.

Table 3: Hybrid Media Performance Metrics

Mix Ratio (Ceramic:Steel) | Energy Savings (%) | Wear Reduction (%) | PSD Narrowing (%) |

30:70 | 10 | 20 | 8 |

50:50 | 18 | 35 | 12 |

70:30 | 25 | 45 | 15 |

From recent binary media research.

Sustainability defines 2025 grinding. Ceramics outshine steel environmentally: lower density slashes energy (30-40% less kWh/ton), curbing CO₂ by 2,000 tons per Mt cement plant. Steel's embodied carbon is 3,006 t/year for fine grinding; ceramics halve it via recycled inputs.

Less wear means fewer replacements, reducing waste—ceramics last 3x longer, cutting landfill media by 60%. Inertness prevents acidic leachate pollution in mining tailings. Plastic alternatives lag in durability, but ceramics lead in eco-efficiency, with LCA scores 40% better. As regs like EU's Green Deal tighten, ceramics enable circular grinding loops.

Selecting ceramic grinding balls demands a systematic approach. Start with application needs: coarse ( >10 mm for initial breakage) vs. fine ( <3 mm for ultrafine).

Step 1: Assess Material CompatibilityMatch hardness to slurry abrasivity—Mohs 9 for quartz-rich ores. Inertness for pH extremes: zirconia for acids.

Step 2: Size and Fill RatioOptimal size = 20-30x target d50. Fill 50-70% volume; mix sizes (e.g., 40/30/20% large/medium/small) for staged grinding.

Step 3: Density and ToughnessBaixoer density (alumina) for energy savings; higher (zirconia) for impact. Test via lab grinds for σ_CS match.

Step 4: Cost-Benefit AnalysisFactor lifecycle: ceramics' premium offsets via longevity. Suppliers like Precise Ceramic offer guides for custom blends.

Table 4: Selection Matrix

Factor | Alumina | Zirconia | ZTA |

Best for Abrasives | High | Média | High |

Energy Sensitive | Excelente | Bom | Excelente |

Cost per Performance | Low | Média | Média |

Consult signature plots for validation.

No silver bullet: ceramics' brittleness risks spalling under shock loads, mitigated by graded compositions like ZTA. Sizing mismatches cause uneven wear—lab tests via signature plots ensure fit. High initial costs? Offset by 30% OPEX savings. Supply chain volatility? 2025's recycled sourcing stabilizes prices.

In corrosive environments, coatings add resilience. For hybrids, monitor segregation with CFD simulations.

AI-optimized mills predict wear via sensors, extending ceramic life 20%. Nano-ceramics (ZrO2-SiC hybrids) target 0.1 μm grinding for quantum dots. In batteries, micro-ceramics preserve lattice integrity, boosting capacity 15%.

Hybrid media—ceramic cores with polymer shells—emerge for pharma, balancing density and cushioning. By 2030, 40% of mills will use smart ceramics with embedded IoT for real-time efficiency.

Wear behavior analysis of advanced ceramic media in autogenous stirred milling.

Ceramic grinding balls aren't just media—they're efficiency engines, transforming performance in stirred mills and beyond. From mining's depths to pharma's labs, their low wear, high purity, and energy thrift promise ROI in months. As we chase sustainability in 2025, investing in ceramics isn't optional—it's essential.

Ready to upgrade? Conduct lab tests for your slurry, explore hybrids, and partner with innovators like Molycop. For more on ceramic grinding balls performance and applications, visit suppliers' resources.

Envie sua demanda,

entraremos em contato o mais rápido possível.

Sanxin Novos Materiais Co., Ltd. foco na produção e venda de grânulos cerâmicos e peças como meios de moagem, contas de jateamento, esfera de rolamento, peça de estrutura, forros cerâmicos resistentes ao desgaste, nanopartículas nano pó